Making 320siWTCC

Sorry, under translation...

(Now, the following texts are translated by machine translation system.)

Part.1

It is a BMW REGENSUBURU factory here.

The body of E90 is flowing the line.

Most seems to be manufacture by the robot.

It is extracted from the line of a commercial car in the middle of body manufacture, and flows on the line only for WTCC machines.

A process original with a WTCC machine still more from here starts.

An unnecessary place is removed, adds lightweight-izing and also spot welding, and raises rigidity.

Attachment of a roll cage is also performed simultaneously.

Work is done carefully [ in handmade business ] and carefully altogether.

The iron pipe is intricately complex just like a jungle gym.

A roll cage is attached by welding.

Merit that's right way this has already called it the pipe frame body rather than monocoque.

Rigidity seems to be high obviously.

Scenery of the driver's seat before a dashboard is attached.

It turns out that the steering mailbox is directly extended from the cage.

A commercial car is the structure which is completely different.

It seems that work is done in the large and clean environment.

The done white body puts on a trailer and is carried to a racing team.

The illustration of an E46WTCC machine is written to the trailer. Is it cool!

It is carried in a garage and work starts still more.

Each part is carefully checked before a work start.

It seems that SAFESA is already applied.

It is painted by the alpin white by handmade business.

being also less -- it is painted carefully.

Part.2

Attachment of resin and a carbon part is started by the body which paint completed.

The structure of the duct inside a front bumper is known.

Air can be efficiently introduced now.

The form of a side step also completely differs from the commercial car.

Is the thing of the shape of a cylinder which is in sight to the front an internal-organs jack?

The rear fender which seems to be very light at the product made from dry cleaning carbon.

Adhesion and a front fender are completely another monochrome in one from a thing with an existing rear fender.

All of these exclusive bahts are the products made from dry cleaning carbon.

A front bumper understands that the duct-like hole to which a lead strap is dedicated has opened.

Surfacer is applied also to a carbon part and it is painted by the body same color.

One by one, a door and a bonnet are attached.

It seems to be orderly clean environment [ it is / the factory here / extensive and ].

Part.3

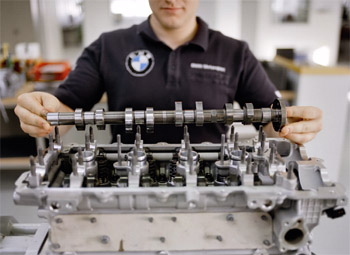

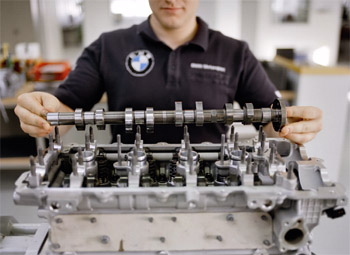

manufacture of engine -- HAMUZU Hall near British Coventry -- a certain BMW Landshut factory

Casting of F1 engine is also just going to be performed.

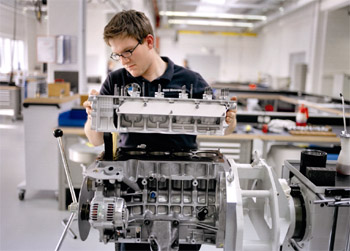

Several sets are used as an object for WTCC machines out of the engine for 320si of a commercial car here.

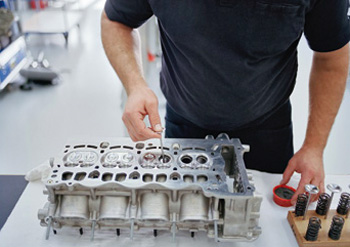

Of course, it is assembled by one-set one set and handmade business.

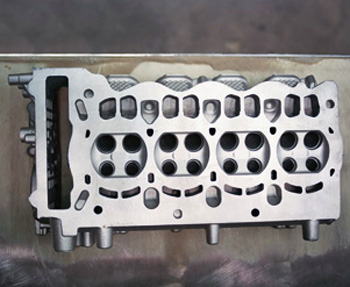

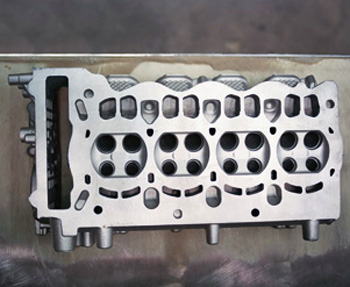

A cylinder head is cleaned by the flat and the burner is also polished up.

also of the burner capacity is carried out, and quality and its accuracy seem to be very high.

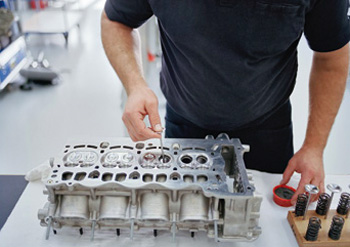

It has incorporated adjusting one valve each other.

The performance of racing engine is influenced by the accuracy of a cylinder head.

Attachment of the valve is perfect.

Careful balance of a crankshaft is made.

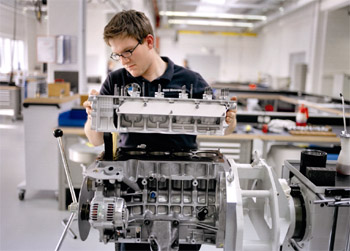

A head is put on a cylinder block.

The axle hole of a cam shaft is also polished up.

A cam shaft should cling.

It seems to be a remarkable high cam.

Is a commercial car another monochrome too?

A valve spring should cling.

it comes out to a slight degree, and engine seems to be completion.

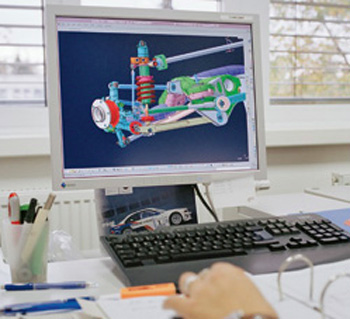

The engine plan by computer graphics.

It is said that the rigidity in high rotation and accuracy are secured by having omitted the operation portion as much as possible.

Part.4

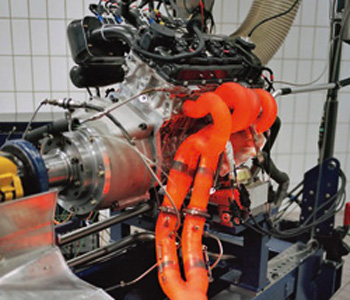

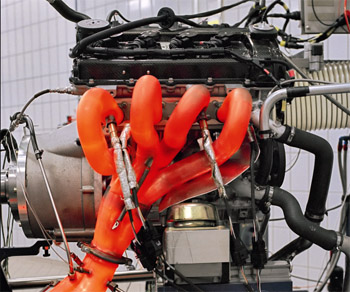

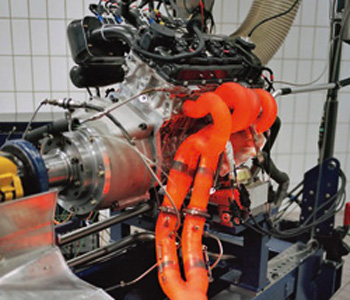

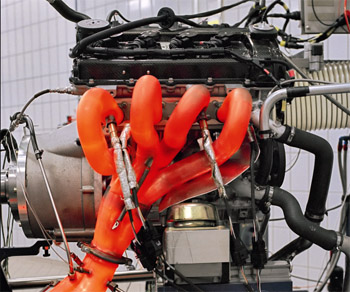

The completed engine is put on a bench and tested.

Under each part check.

Red exhaust pipe.

The engine which finished the check is carried in the body still more.

Engine is carried in remarkable back slippage of the body, and optimization of weight balance [ before and after ] is attained.

Work is done carefully.

The character of "BMW Power" is minced by the reverse side of an engine hood.

The gear box is beforehand attached in engine here.

With the usual 5 速 manual gear box, the gear ratio is optimized for every circuit.

When adopting the sequential gear box of 6 速 incidentally, a 30kg weight handicap will be imposed.

Loading in engine and gear box one is performed so that it may be made to slide from the front.

A check will be performed by the chassis dynamo if engine and a gear box are carried.

Although it is the same 2l. engine, compared with 6 cylinders, full length is short and a merit's is [ 4 cylinders ] lightweight.

It is said that the maximum output has generated 275ps(es) of the 6-cylinder engine for WTCC in 2005, and this level.

Part.5

A steering and pedals are incorporated although there is no part to the extent that it is called interior design.

A steering is attached.

Pedals are attached.

Since three pedals are collectively attached in the same panel, they can unite a position according to the height of a driver.

It is a pedal just like Fomula machine..

It is the machine of ARESSANDORO ZANARUDI here.

Only by hand, his machine with trouble in a leg is converted so that driving may be possible.

Since it is a racing car, although there is no air back, of course, seemingly, collision safety will be higher than three series of a commercial car.

Part.6

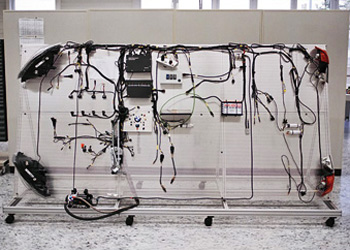

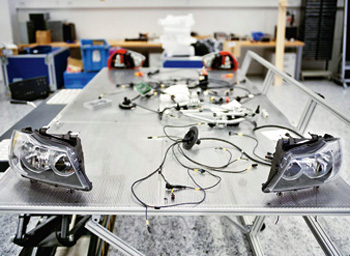

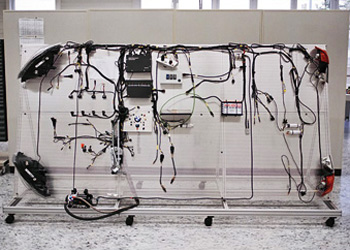

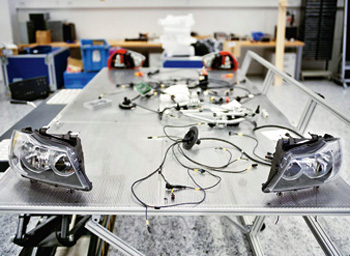

This is all the electoric systems of 320siWTCC.

Improvement in convenience and lightweight-ization are attained by adopting the CAN-BUS system which transmits two or more information same with a commercial car.

Work is started after arranging exactly.

It attaches in a body carefully.

Since there is neither lining nor a carpet, wiring is still unreserved natural.

A commercial car is such simple wiring that it does not become a comparison.

It is said that an engine management system is perfect product which the specialist of Munich developed.

The management in an engine room is also simple and beautiful.

Part.7

A front window is stuck with a sucker.

Two persons attach together.

A brake and a suspension should cling.

It seems to be an absurd damper with high accuracy.

That's right which developed the optimal damper in collaboration with Sachs so that it might correspond to a wheel wider than a commercial car and big camber.

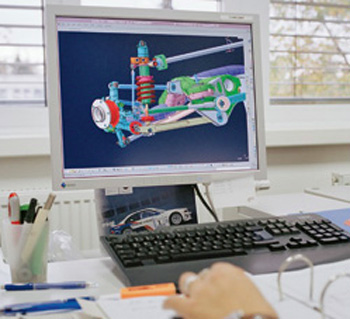

The plan of the suspension by computer graphics.

It is said that it was a difficult subject how the newly developed multi-link formula rear suspension is fitted to a racing version.

An exhaust pipe should cling.

It is the main silencer of a wonderful design.

Part.8

It is based on a cutting sheet except the color of a base.

Gradually, it has come seemingly to be a racing machine.

Part.9

The situation of development of an aero part is introduced.

The view from a wind tunnel observation room.

The flow of the air from a roof to rear spoiler is a very important point.

The flow of air is viewed by smoke.

That's right which what was superior to E46 by last year in aero dynamics with a repetition of a test and improvement completed by wide body-ization although air resistance will increase.

It is written to the wall as "BMW Windkanal (wind tunnel)."

It is said that BMW Motorsport has received positive support, such as a wind tunnel experiment place and test course use, from the commercial car manufacture engineer in development of 320siWTCC specification.

All various data is managed by computer.

Part.10

...Click to see large image

The shot from which the wide feeling of a front view is transmitted.

It is clothed in the newest BMW Motorsport color of F1 inheritance.

...Click to see large image

At a side shot, a wide fender will be unclear and will look common with it being unexpected.

...Click to see large image

At the shot from after slanting, a rear wing. Gets up and the wideness of a fender is transmitted well.

...Click to see large image

A rear view is the form which has sense of stability very much.

BMW Motorsport poured out total energy and development of 320siWTCC was performed in nine months.

Delivery of cars should be started from December, 2005, and when this machine is in May, 2006, 17 sets deliver it.

It is said that the price of those days was incidentally abbreviation 27,100 circle in Japanese yen conversion.

International Top

International Top English HOME

English HOME Contact Us

Contact Us